Sunreef Catamaran Design & Build Quality

Sunreef catamarans have launched more than 150 large sailing and power catamarans built in advanced composites. All of them are safely sailing the seas and over the many years Sunreef catamarans have provided a luxurious and comfortable environment for their owners.

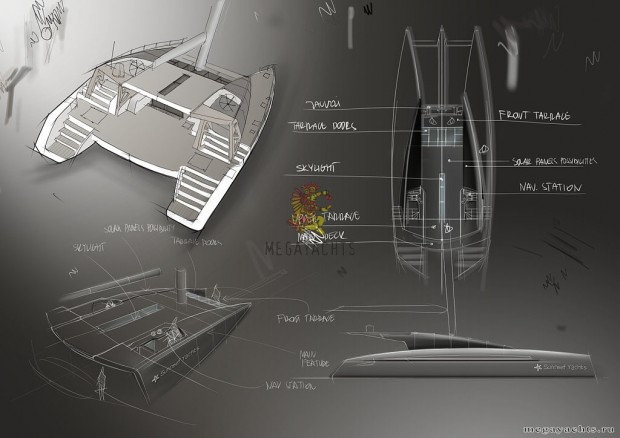

Sunreef in-house naval architect team design hull shapes so that their catamarans can be seaworthy and comfortable. It is a complex process involving a large number of important decisions about shape, structure and materials. The purpose of the design process is to optimize the performance and reliability of the hull, taking into account the structure as a whole, and also to minimize the cost-price and weight reduction. In the design stage, the greatest challenge is to find the perfect balance between aerodynamics and hydrodynamics, combining all the elements into one single unit. The aerodynamic properties are crucial in determining how well the sails can extract energy from the wind. The hydrodynamic properties define how the hull can transfer this energy into speed.

Design, materials and processes are closely linked, and this is particularly clear in the development of Sunreef yachts models. With the necessary know-how, the builder can take into account specific hull performance requirements right from the beginning. The fact that Sunreef has this expertise also lets them benefit from the experience acquired in all the different phases of developing and producing a new hull design. Similarly, optimizing the production process can have an important influence on the overall design.